"Built to a Spec"

Aren't ALL Ethernet Cables Built to the Ethernet Spec?

We've spent a lot of time discussing the problem of noncompliant Cat 5e, 6 or 6a cabling over the last few years, and we've found a surprising number of people who just do not believe what the test reports show. One objection we've often been met with takes more or less this form:

"All of these cables are built to a spec, and network equipment is designed to run through cable built to that spec."

This used to puzzle us, to the point that we hardly knew what to say; after all, the very thing we were pointing out was that most of the Cat 5e, 6 and 6a cabling on the market did NOT comply with the specification, so it seemed like an odd objection to pose. But after giving it some thought we think we know what the people who say this mean; let's address that, and see what's the matter with it.

Many people -- perhaps most -- when they hear that something is made to a specification, imagine what amounts to a sort of "construction spec." Such a specification might consist of a drawing showing how the cable is to be laid out, or a procedure for manufacturing it, along the lines of "Take eight 24 AWG copper wires with insulation .01 inch thick, twist them at these rates, separate them with a spline and extrude a jacket over it, and that's Cat 6." If that were the type of specification we were dealing with, the way to check compliance with the spec would be to strip the jacket off and have a look: were the assembly directions followed?

While the engineers at firms that manufacture bulk cable do indeed produce design drawings of cables (here is Belden's diagram of the internal layout of our Series-FE HDMI cable, for example), and do indeed produce "recipes" that instruct factory personnel as to how to make the product, these types of designs have no direct correspondence to what's in the spec. Why? Because the specification for Cat 5e, 6 and 6a cable is not a "construction" spec but a PERFORMANCE spec.

We keep a copy of the TIA specification for Ethernet cabling (there's also a similar ISO specification) handy here at our shop. We'd spell out exactly what it says, but TIA is a bit persnickety on the copyright front and a copy costs over $200, so we don't want to run afoul of TIA's rights by republishing the relevant portions here. But what you'll find, if you care to spend the money or have a friend who has a copy at hand, is that there's actually very, very little in the specification about what the cable should look like and what it should be made out of -- and nothing in the way of directions that would tell anyone how to make it. No twist rates for the pairs, no dimensions; no specifications requiring splines, shields, jacketing materials -- none of that at all. There's no such thing as a cable "built to" the construction details in the spec, because there are no construction details in the spec.

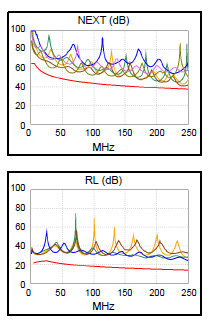

What IS in the TIA spec, however, is a range of performance criteria. For patch cables the most critical of these criteria are return loss and crosstalk. TIA doesn't care how you get your results -- if you can figure out how to make a compliant cable out of banana peels and old carburetors, it's a compliant cable, so long as it meets the electrical performance criteria for return loss and crosstalk. These criteria can be seen, in test reports, as limit curves -- to the right is a pair of charts showing crosstalk and return loss from one of our Ethernet cable assemblies, showing a compliant cable. The red curve is the limit (which varies with frequency, from left to right on the graph), and the other colored traces are the measurements taken from testing each of the six pair-to-pair combinations (for crosstalk) or each of the four pairs (for return loss) in the cable. The testing process consists of a series of frequency sweeps on the various pairs, with measurement of results against the spec criteria. As long as all of those other traces are above the limit line, the cable is compliant.

One problem, of course, with electrical performance-based criteria is that they're invisible to the naked eye. Nobody can pick up a piece of Ethernet cable, give it a good once-over from both ends, and tell you based on personal inspection whether it's compliant. There is, in fact, often very little obvious external difference between well-made cables that pass spec by many dB and poorly-made cables that fail the spec by many dB. Return loss depends upon tiny-scale consistency in construction and materials; crosstalk turns upon not only that, but the complex interplay, over time and distance, of the resulting fields surrounding the pairs when in use. The result is that there really, truly is no way to know whether a cable is compliant without running the tests the specification requires.

Understanding this distinction between a "construction" spec and a "performance" spec is an important key to understanding what the roles of manufacturing quality and of testing really are in Ethernet cable performance. Network equipment is NOT designed to shove signal faithfully down any bundle of eight wires that more or less looks like an Ethernet cable and is hooked up to the correct connector pins on each end; it's designed to work with cabling meeting the electrical performance requirements of the specification, and only high quality manufacturing, followed up with specification-based testing, can assure that you have compliant cabling going into your installation.